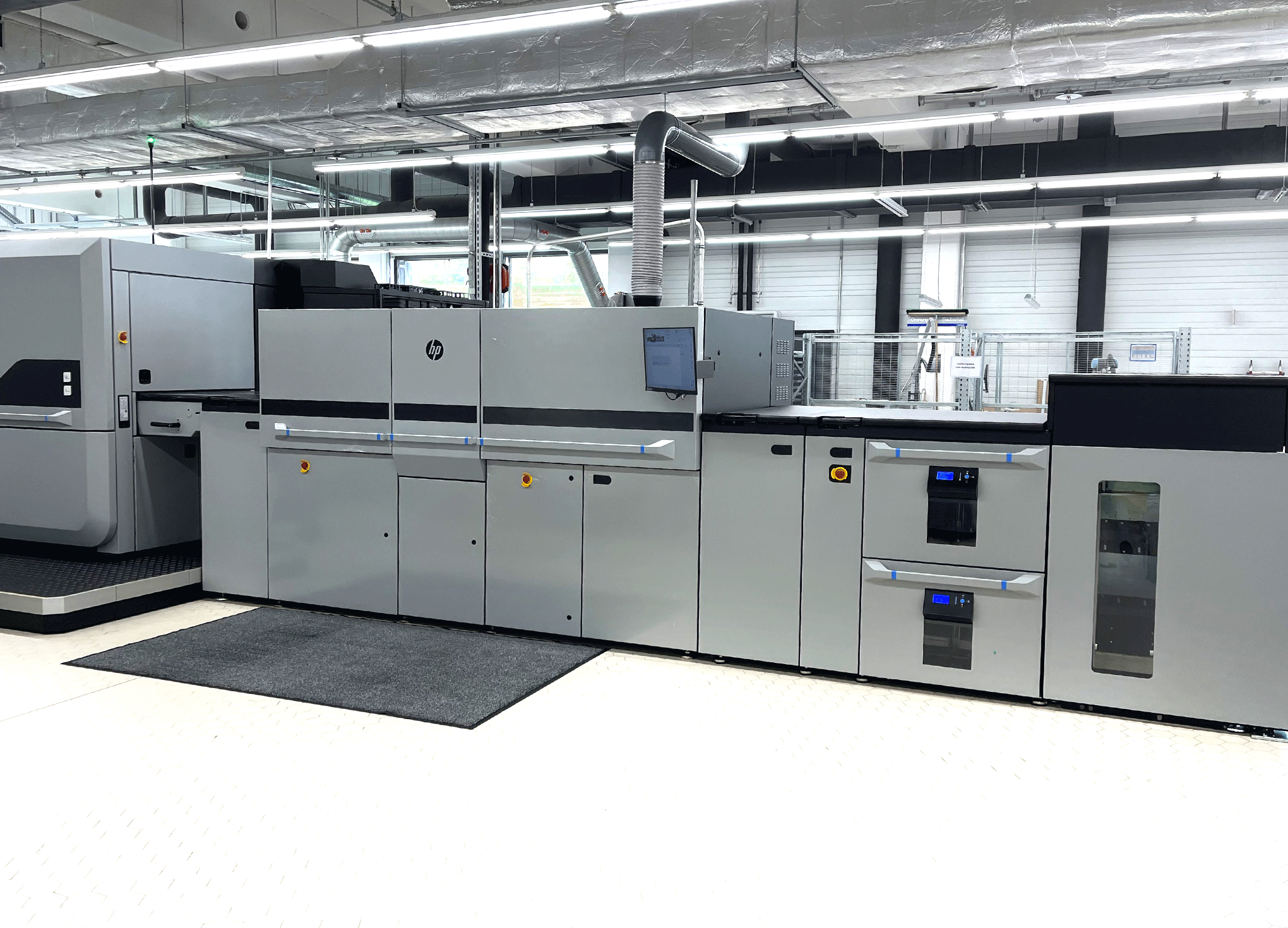

HP Indigo 35K

We have replaced our HP Indigo 30000 with an HP Indigo 35K. The new digital press can produce dozens of jobs a day and up to one million B2 sheets a month. In addition to the high capacity and quality of the HP Indigo 35K, the decisive factor in the decision was the good cooperation with HP.

“In recent years, we have seen above-average growth in digital printing. We work a lot with start-ups as well as medium-sized companies and corporations. By means of digital printing, it is possible for us to implement projects for personalization as well as serialization. We can handle high volumes as well as very small batches. Furthermore, especially in the context of sustainability, piece-precise productions with fast delivery times can be implemented in the field of PACKAGING DIGITAL. Some of our customers have already implemented ‘Packaging on Demand’ with us to minimize warehousing concepts and overproduction,” explains Martin Bruttel, Managing Director, colordruck Baiersbronn.

We have been relying on HP Indigo digital presses since the establishment of the “PACKAGING DIGITAL” business unit in 2016. One of the decisive factors for the new investment was the flexibility of the digital press: For example, the HP Indigo 35K can produce Advent calendars, folding boxes or blister cards from batch size 1 – all products that are in high demand from our customers.

Other criteria that spoke in favor of the new HP Indigo 35K were the food-safe inks with outstanding brilliance, as in offset printing – both for spot and spot colors and in terms of color stability. The low macuature that occurs during printing also paid off on the new press. The entire process workflow, from the order to the press, is fully automated and ensures a high level of time savings for the large number of jobs.

“The investment in the new HP Indigo 35K underlines our commitment to providing our customers with the best products by using the latest technology. At the same time, it enables us to grow together with our customers,” Martin Bruttel continued. “Thanks to the new HP Indigo 35K, we are increasing our production efficiency and quality and strengthening our market position.”

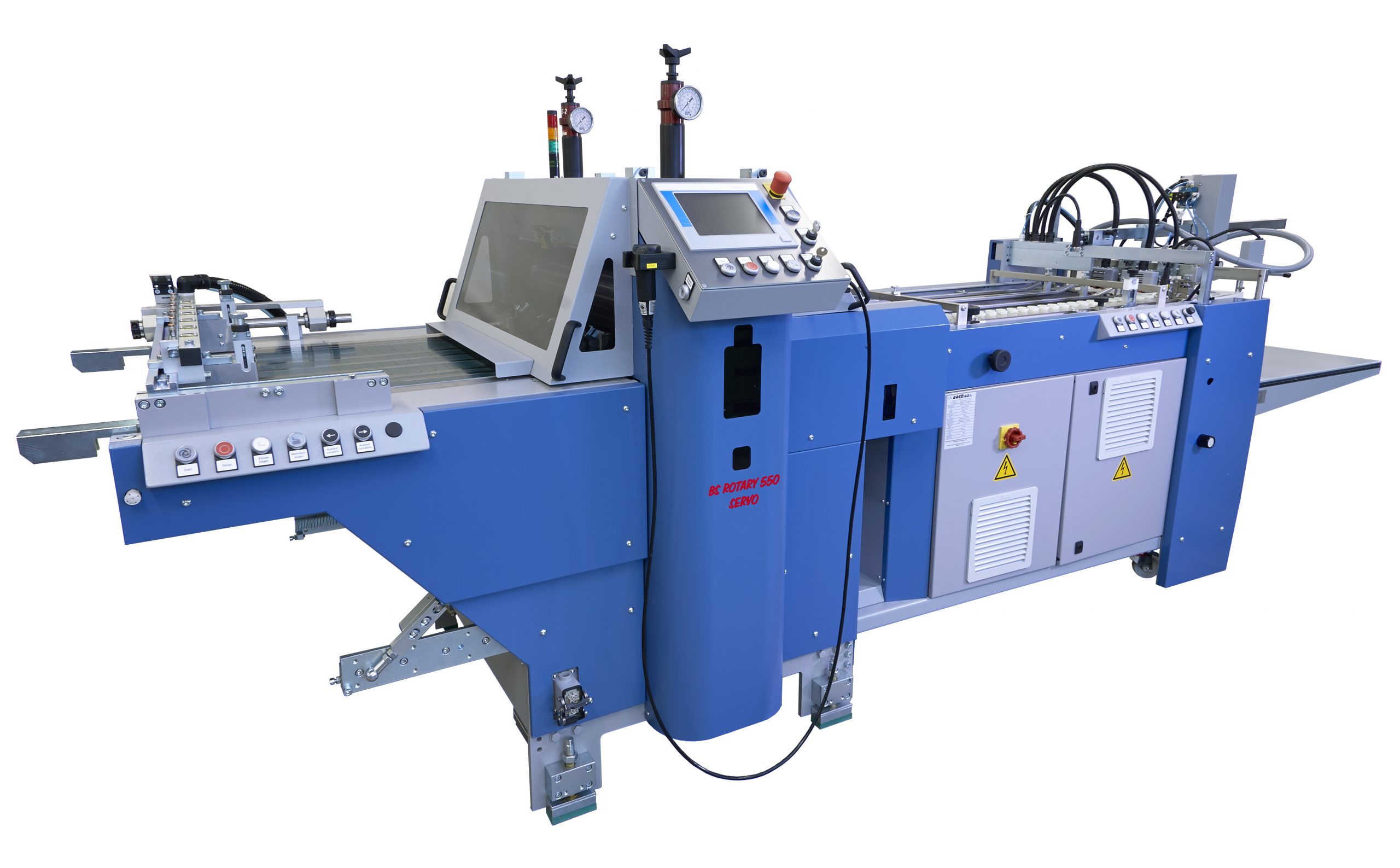

BOGRAMA BSR 550 Servo

In addition to the new printing press, we have also expanded our production portfolio with a BSR 550 Servo rotary die cutter from the manufacturer BOGRAMA. This enables faster and more efficient finishing of single sheets.

The decision to invest in the machine is due to the above-average growth in the “PACKAGING DIGITAL” division in recent years. In addition to the existing plotter, which is suitable for very short runs, and the tool-less laser die-cutting machine, the BOGRAMA-BSR 550 Servo complements the production portfolio as the third die-cutting machine. With its versatile functionality, the die cutter can punch, die cut, perforate, crease and blind emboss – opening up a wide range of possible applications. The rotary die cutter is also characterized by its simple die pull technology, short makeready times and high-precision register, which contributes to cost-efficient production. In addition, the machine is equipped with an automatic discharge of the cut-off grids and simultaneous stripping of the inner die-cuts.

This further increases efficiency and ensures clean delivery of the die-cuts or their direct further processing in downstream machines. With the integration of this new rotary die cutter, we are setting another milestone in the digital printing industry and underlining our commitment to using innovative technologies to meet market requirements and always offer customers the best possible solutions.